Car manufacturers are relentlessly pursuing weight reduction to improve fuel efficiency and performance, and one often-overlooked area is the humble car seat. Despite advancements in materials like lightweight steel and aluminum, seats remain surprisingly heavy – a typical set weighing around 50kg (110lbs). Now, innovative technologies and sustainable materials are poised to dramatically change that.

The Hidden Complexity of Car Seats

Most drivers barely think about the engineering packed into their seats beyond comfort. But beneath the surface lies a complex structure incorporating frames, electrics, heating/cooling systems, and critical safety features like airbags. The challenge is to balance lightness, strength (for crash protection), minimal space usage, and cost-effectiveness.

According to Thyssenkrupp, a supplier of lightweight steels, even the frames alone add roughly 12.5kg per front seat. Combined front and rear, seats account for a substantial portion of a vehicle’s overall weight. Reducing this weight has become a priority.

Pioneering Solutions: From 3D Printing to Bio-Based Materials

Several approaches are being tested to cut down on seat mass. Toyota has experimented with 3D-printed seat structures, while Porsche has already developed a fully 3D-printed bucket seat. Braunschweig University of Art even created the “Concept Breathe” – a 3D-printed seat with a biodegradable plastic skeleton and 38 active cushions.

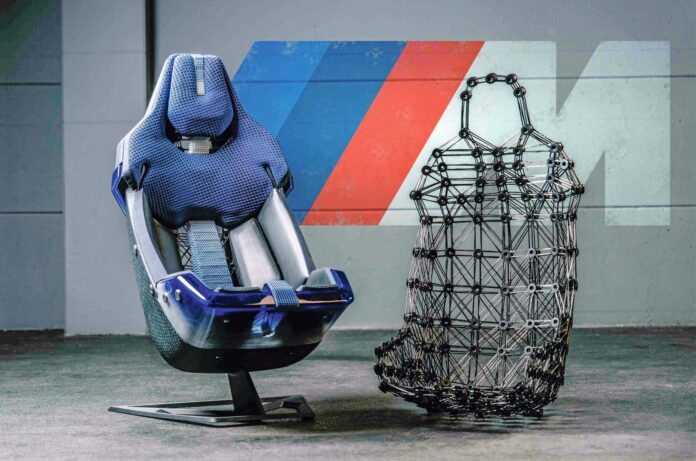

However, BMW’s latest approach may be the most radical. Their “M Visionary Materials” seat uses robotic filament winding, a process where a robot layers resin-infused filaments onto a frame. This method, developed with Gradel Light Weight, results in a structure that is reportedly 60% lighter than conventional designs without sacrificing strength.

Why This Matters

The pursuit of lighter car seats isn’t just about saving a few kilograms. The automotive industry faces increasing pressure to reduce emissions and improve efficiency. Every pound shaved off a vehicle translates into fuel savings and lower carbon footprints. The shift towards sustainable materials, like bio-based leather alternatives, also aligns with growing consumer demand for eco-friendly options.

“The technology completely does away with conventional structures.” – BMW, describing the impact of filament winding on seat design.

Reducing seat weight is a tangible, achievable step toward more sustainable and efficient vehicles. As materials science and manufacturing techniques continue to advance, we can expect even more dramatic reductions in the future.